Services

Our manufacturing company offers a wide range of services, including product design, prototyping, fabrication, and assembly. We have a team of skilled professionals who ensure top-quality manufacturing solutions for our clients.

01.

Automation PLC ( Allen-Bradle- Omron – Siemens- Mitsubishi -Delta)

Business workflow automation software empowers you to take control of a complex IT landscape by delivering seamless digital automation from a single, unified platform. Speak to our team and find out how our solutions provide a single pane of glass for all automated processes, regardless of where they might run. This gives a standardized way to design jobs and workflows that integrate all the technologies you use. we do more than supply best-in-class automation software, our consultative approach ensures you don’t just adopt automation, you harness it to transform your business outcomes

Digital district s a Tier 1 partner offering an impressive breadth of support and ease for enterprise clients. We don’t just help you choose the right solution, we can also reduce your time to implementation by months and provide ongoing support. You can also opt in to find out about any updates or new features to keep your software working at its optimum for your specific use case and business goals

02.

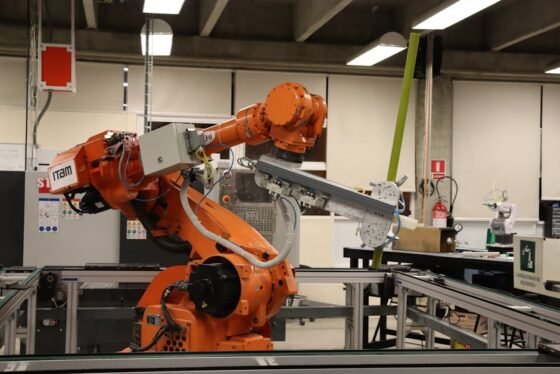

Handling Systems - Production Of Conveyor System

Bastian's expertly designed conveyor systems replace manual transport processes to create more reliable, ergonomic and organized operations. Whether purchased as standalone pieces of equipment or as part of larger automated systems, our solutions increase throughput, relieve bottlenecks and maximize the productivity of your labor force. Conveyors can help automate a variety of processes, including transporting, sorting, loading, unloading, palletizing, order fulfillment and more.

Digital district s a Tier 1 partner offering an impressive breadth of support and ease for enterprise clients. We don’t just help you choose the right solution, we can also reduce your time to implementation by months and provide ongoing support. You can also opt in to find out about any updates or new features to keep your software working at its optimum for your specific use case and business goals

Such as the following:

A. Automated Case Flow Systems

B. Pallet Conveyors

C. Accumulation Conveyor

D. Vertical Spiral Conveyors

E. Sortation Systems

F. Merge & Combiner Conveyors

G. Belt Conveyor

H. Roller Conveyor

I. Overhead Conveyor

J. Modular Plastic Belt Conveyor

K. Gravity Conveyor

L. 24-Volt Roller or Belt Conveyor

M. Portable Conveyor

N. Pallet Monorail

O. Pallet Handling Solutions

P. Print & Apply Labelers

Q. In-Line Scales & Automated Weighing

R. Robotic Document Inserter

03.

Maintenance (electrical and mechanical)

Maintenance for electrical and mechanical systems, often called M&E maintenance, involves the scheduled and reactive upkeep of a facility's power, lighting, heating, ventilation, machinery, and other infrastructure to ensure safe, efficient, and continuous operation. This work includes routine inspections, repairs, testing, and replacement of parts to prevent unexpected breakdowns, reduce operational downtime, and enhance overall performance and safety within an industrial setting.

Such as the following:

A. Central kitchen equipment maintenance

B. Restaurant equipment maintenance

C. Food production line maintenance of all types

D. Mechanical and electrical equipment maintenance

E. Refrigeration and air conditioning maintenance

04.

Fabrication

It is the formation and manufacture of mechanical and electrical parts according to the customer’s requests.

Including the following:

A. Piping fabrication

B. Stainless steel fabrication

C. Tank manufacturing

D. Electrical panel manufacturing

E. Water station manufacturing and maintenance

F. Fire system manufacturing

G. Processing unit manufacturing and installation

05.

Design, sale, maintenance and warranty

food line machine services encompass the design of customized, automated production systems, the sale of new and used equipment from manufacturers , and ongoing maintenance, including cleaning, repair, spare parts, and predictive upkeep to ensure efficiency, hygiene, and longevity. Specialists offer everything from consultations and installation to comprehensive maintenance contracts, with a focus on modular designs that integrate seamlessly into a bakery's workflow to maximize output and product quality

Including the following:

A. Bakery production lines

B. Croissant production lines

C. Maamoul production lines

D. Pizza production lines

E. Sweet production lines

F. Chocolate production lines

G. Meat production lines

H. Juice production lines

I. Sauce production lines

J. Dairy production lines

Our projects

Installation of a toast production line at Fonti Company

06.

Spare parts supply

We are able to provide the necessary mechanical and electrical spare parts for all equipment. We can also provide alternative spare parts with installation and operation guarantees.

A. Electrical spare parts

B. Mechanical spare parts

C. Air system spare parts

D. Hydraulic spare parts

E. PLC spare parts

07

Project Management

Discipline of applying knowledge, skills, tools, and techniques to project activities to meet project objectives, which are constrained by scope, time, and budget. It involves the initiation, planning, execution, monitoring, and closing of a project, ensuring resources are managed and risks are controlled to deliver a valuable final product on time and within the set parameters. Project management is a crucial process for organizations to achieve their goals, coordinating personnel, finances, and technology to ensure successful completion of projects across various industries.

A. installation and commissioning for machinery

B. Upgrade machinery

C. Implementation of electromechanical projects